steviejr92

Authorized Vendor

ProCo / Fuzzdog 3-Band Rat

This is a request. Fuzzdog tweaked a the classic Rat circuit a few years ago. It includes the "Reutz mod", a diode selector switch for assy...

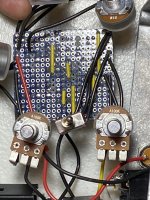

So this is the stripboard layout I’m following for a rat here’s the problem I get bypass but nothing when engaged I checked the ic that’s fine I biased the 2n5457 correctly it’s at 4.6v. The only thing that is getting me is the wiring the board doesn’t have an output simply says wire output to volume leg 2 which I did but then how do I wire up the footswitch? I followed this diagram here

How To Turn A Populated PCB Into A Guitar Pedal | DIY Effects Pedals

One of my first failed DIY guitar pedal projects was when I purchased a PCB for a TubeScreamer. The board came with a detailed component list and putting it together seemed too good to be true. However, once I’d put all the pieces in place I didn’t have a clue how to actually turn it ... Read more

Notice pin 8 and 9 are not connected the diagram is asking to put and LED for pin 8 and pin 9 you need an output for from the board the dirt box diagram doesn’t have one listed. Thanks for the help in advance.

Last edited: