geadapedals

New member

Hello,

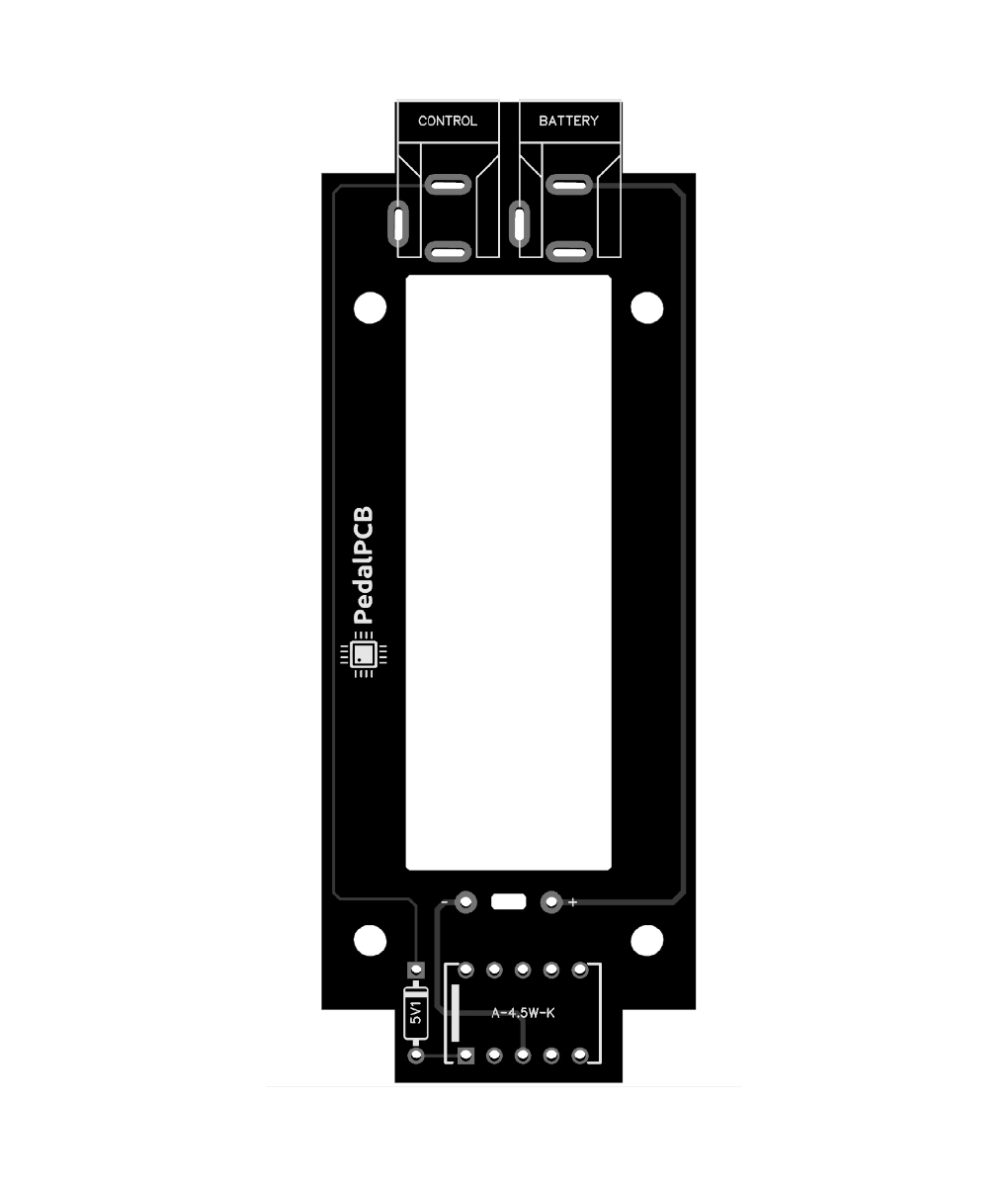

I'm building my first pedal, the Sunflower Fuzz, and did some research and basically everyone says fuzz works best with batteries, so I guess I will also do it.

I don't know anything about pedal building so I have no idea how to modify the pedal, so I was hoping someone could guide me on how to do it step by step like you would explain to a 5 year old

Also came across a battery kill switch mod, I guess to increase the duration of the battery. Is it worth it? If yes, how can I do it?

Thanks

I'm building my first pedal, the Sunflower Fuzz, and did some research and basically everyone says fuzz works best with batteries, so I guess I will also do it.

I don't know anything about pedal building so I have no idea how to modify the pedal, so I was hoping someone could guide me on how to do it step by step like you would explain to a 5 year old

Also came across a battery kill switch mod, I guess to increase the duration of the battery. Is it worth it? If yes, how can I do it?

Thanks