Fingolfen

Well-known member

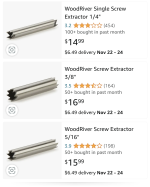

So I've been trying to build a guitar, and the project has pretty much been cursed from the outset. I got it to the point to where I was trying to install the Hipshot bridge. carefully drilled out the holes for the wood screws using the recommended bit... then one of the b****es twists off and breaks within about 3mm of being set. So now I've got a wood screw stuck in the guitar. I've tried several things to get it out - there's no head, so I haven't been able to use one of those reverse thread gizmos. There are some small screw removers, but they're too fragile to get a stainless screw out of maple + mahogany. I'm at my wits end on this thing and sadly have a ton of cash invested in it including the finish (which the idiot effed up requiring a re-fret) and the aforementioned re-fret...

Thoughts????

Thoughts????