giovanni

Well-known member

First of all, phrasing.

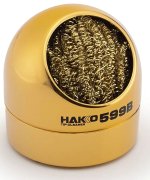

Second, I pulled out my iron yesterday and started going at it but I noticed a little bit of gunk on the very tip that I could not shake off. Also phrasing.

In seriousness, the conductivity of the tip seems a bit diminished and I had to get the right angle to enable the solder to flow (I use a small conical tip that I really like). Tinning didn’t seem to help. It does look like there is a bit of oxidation or something on one side which may be causing this. I hadn’t been able to use the iron in over a year so maybe it’s a fully oxidized piece of solder? I haven’t tried cleaning it yet, what method would you recommend? Would IPA work? Or do I need something else?

Second, I pulled out my iron yesterday and started going at it but I noticed a little bit of gunk on the very tip that I could not shake off. Also phrasing.

In seriousness, the conductivity of the tip seems a bit diminished and I had to get the right angle to enable the solder to flow (I use a small conical tip that I really like). Tinning didn’t seem to help. It does look like there is a bit of oxidation or something on one side which may be causing this. I hadn’t been able to use the iron in over a year so maybe it’s a fully oxidized piece of solder? I haven’t tried cleaning it yet, what method would you recommend? Would IPA work? Or do I need something else?